The Disappearing Art and Science of Real Process Management

This is a follow up on an article I wrote earlier this year titled Time, Speed and the Process Revolution: Why Are These Disciplines Disappearing? click here if interested. That article did not engender much discussion on LinkedIn but it did among the readership at my website www.billbigler.com. If my observations are correct…that process disciplines from a management viewpoint are disappearing, I would like to try one more time to raise a clarion call that this is a problem. I ended the article cited above by asking where have real process disciplines gone? Subsumed under Agile management or ERP systems? Or have they just faded as other management approaches have gained popularity?

Please let me provide a few caveats. First, I work almost exclusively now in mid-sized firms and not in business units of larger corporations like I used to do. Thus, my observations about management-oriented process disciplines disappearing may only apply to mid-sized firms. Secondly, I make the assumption based on my experience and some research that process disciplines like we will discuss are very valuable for firms. You might disagree.

So the purpose of this article is to provide a review of what we know or should know about effective process disciplines. This will hopefully set a baseline of knowledge and not seem condescending. The article will also pose the question are these process disciplines valuable for for-profit firms? If you agree with me that they are valuable we then ponder the question why are they disappearing? Lastly, I will show my hand and will make the point that I view this as a serious problem. On the other hand, firms that continue to uphold these process disciplines should see a speed-oriented competitive advantage over firms who will never embrace these disciplines or who have abandoned them. Indeed my approach to strategy execution assumes and relies on a cadre of “Process Champions or Owners”. While maybe idiosyncratic to me, I have had to adapt other approaches to strategy execution as real process management and the process champions/owners are just not there in the firms with which I now work.

This article will be like several I have published. It will use a flow of figures to tell the story as “a picture is worth a thousand words”. Thus I can focus on what I have learned for clients over the years and will allow us to not get lost in the weeds. As you will see, at a logic level process disciplines are pretty simple and straightforward. The “devil is in the details” though. OK here we go:

Executive, Operating and Support Processes Overview

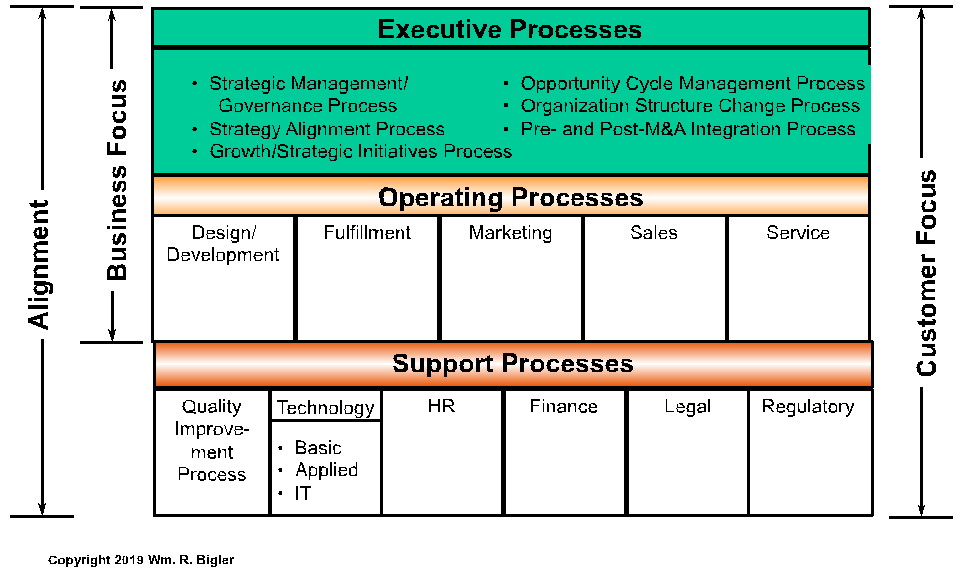

From a management perspective, processes can be categorized as Executive, Operating or Support processes. Figure 1 is from the prior article and gives examples of a few of each kind of process.

Figure 1: Executive, Operating, and Support Processes Examples

A process is a cross-functional stream of work that cycles either continuously or at intermittent times. Thus a process is different from a project that has a defined start and end. As examples, think of your Executive Process of Strategic Planning or your Operating Process of Sales or your Support Process of Key New Hires in Human Resources. These example processes and all other key processes can be mapped as to which functions are involved and when in the process they get involved. The overall process can be measured in terms of its cycle time (speed) and the amount of re-work typically found in the process. There are other process measures, but these two are the most important from a management perspective. Too long of a process cycle time usually means there are non-valued added steps in the process or it is not appropriately automated. And almost always long process cycle times cause a lot of frustrating re-work or vice versa, re-work causes long process cycle times. Long cycle times and re-work are destroyers of organizational performance in today’s business world.

How to Map a Process From a Management Perspective

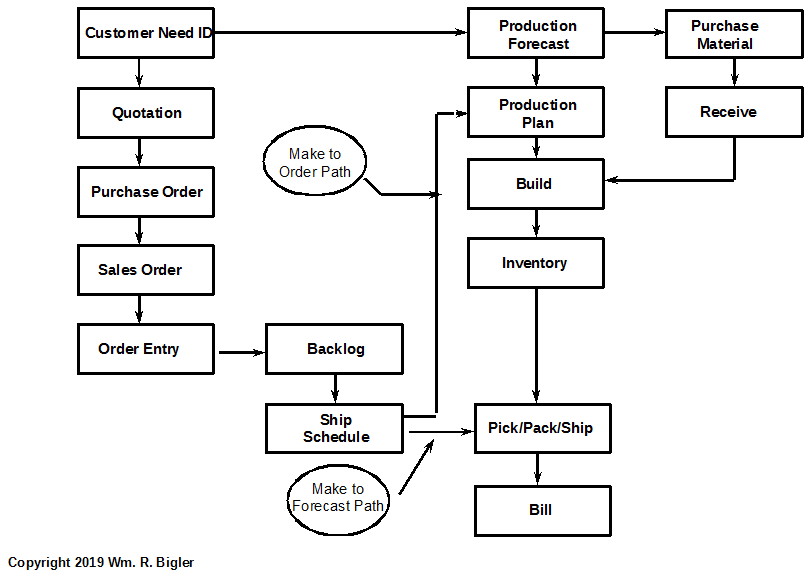

Figure 2 depicts how a Fulfillment process (Make-to-Order in this example) looks using a nomenclature found in software development and is how I think many people still view a process. A fulfillment process covers the steps from when a customer knows they want to buy, places an order and your company fulfills that order to delivery:

Figure 2: Conventional Map for Fulfillment Process

While useful for software development and other purposes, this view of a process is virtually useless for management purposes. Figure 3 recasts this process with a view that can really aid management:

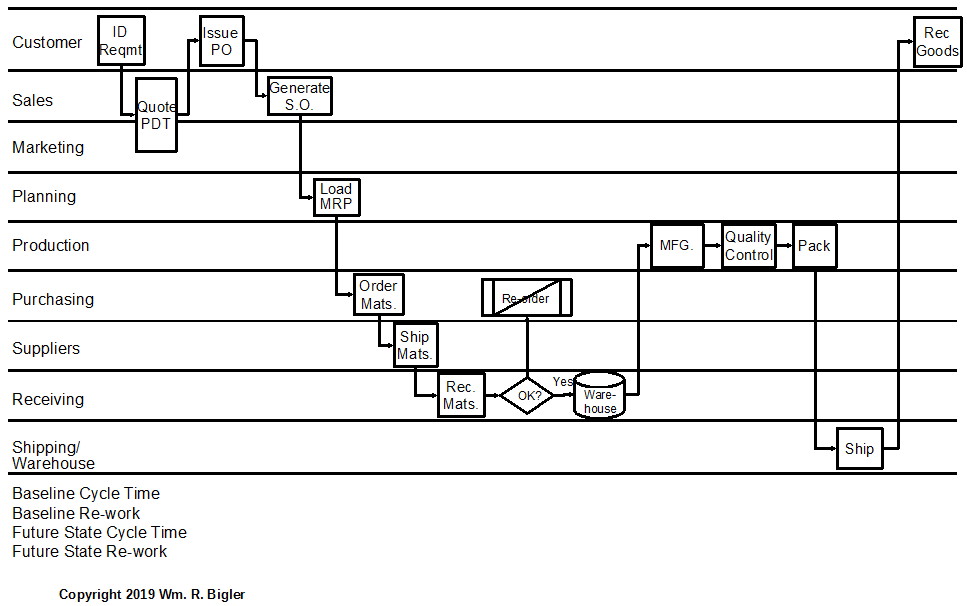

Figure 3: Cross-Functional Flow Diagram Approach: Fulfillment Process Make-to-Order

Here I must give credit where credit is due again. I learned management-oriented process disciplines during my time at the Thomas Group in the late 1990s. Thomas Group was one of two leading Operations Excellence consulting firms at that time, and the two and a half years there were some of the best in my career.

As one can see, in order to map a process so it can aid in management one starts by listing the functions involved in a process to the left of Figure 3. The functions are listed from top to bottom in the order that that functional area gets involved in the process. The person or team doing this work first starts with mapping the current or Baseline process. Some people refer to this as the “As-Is” process. Its baseline cycle time and amount of re-work can be measured and are recorded at the bottom of Figure 3. The key in this exercise is to lay out what the “Future State” process should look like. Non-valued added steps can be eliminated and some newer more value-added steps can be included.

How is the Future State process derived? It is from asking customers and where they find barriers and frustration in the Baseline process. It is also trying to assess which competitors have best-practice processes or even best-practice parts of a process. These build to form a view of what the Future State process could look like.

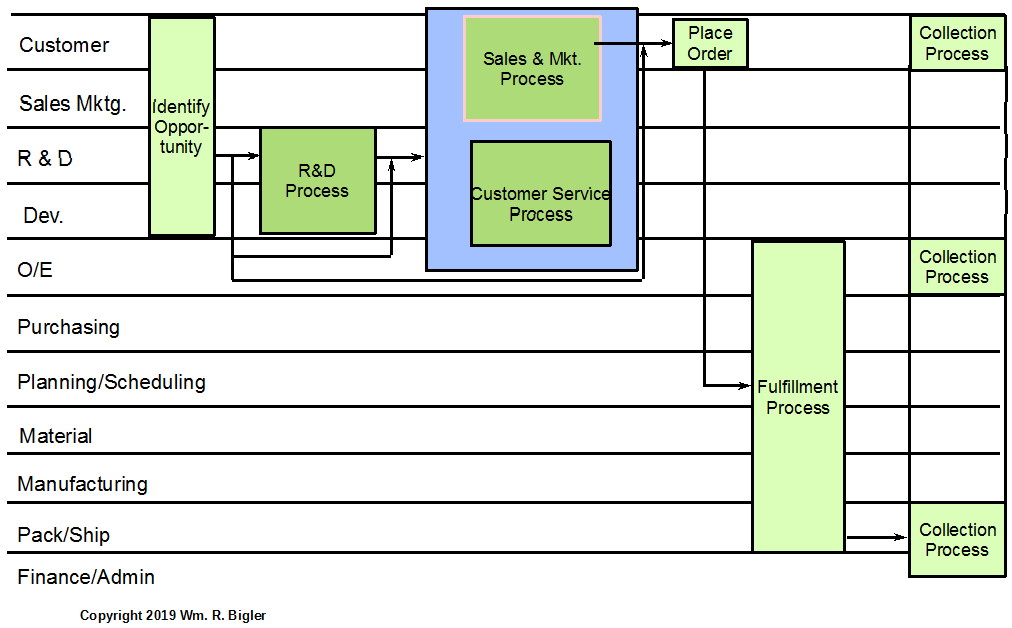

The beauty of mapping processes this way is that one can focus on Speed increases and Re-work decreases. Let’s use a simple example. Figure 4 depicts a “Level 0” process and is the highest level depiction of a process. In this case, Figure 4 depicts a Level 0 view of an entire company or business unit within a corporation. Levels 1 through 3 can portray increasing levels of granularity and detail depending on what is needed for clarity and to aid disciplined action. These levels are not shown here.

Figure 4: How to Map Processes – “Level 0” Example

Assessing Process Speed and Amount of Re-work

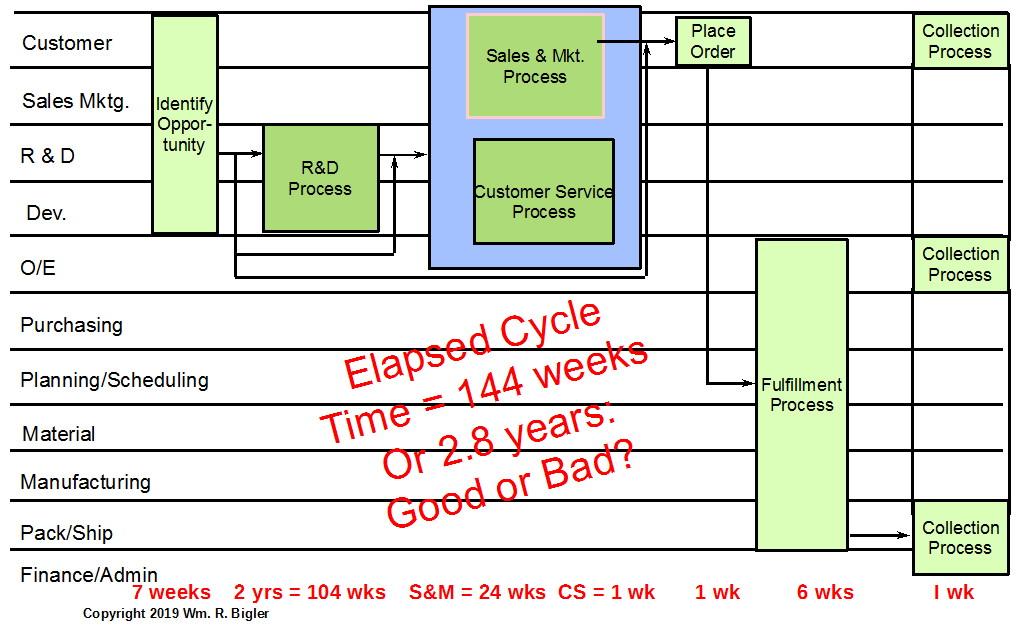

Figure 5 shows the same Figure but with hypothetical cycle times for parts of the overall process measured and recorded in Red at the bottom. The hypothetical total cycle time adds to 144 weeks or 2.8 years and poses the question “Is this Good or Bad?” Of course, the answer is it all depends on what customers need and want from the process and what best-in-class looks like. As I shared in the prior article, we estimated the cycle time for a similar holistic process at a major lighting manufacturer to be almost 7 years! Their big-box retail customers were dissatisfied. And we benchmarked against General Electric Lighting, Phillips and two smaller nimble/agile competitors and found the best-in-class process cycle time to be 14 months with very little re-work. Seventy months or 5.8 years needed to be removed from this process and re-work had to be drastically lowered for this lighting firm to be competitive.

Figure 5: How to Map Processes – “Level 0” Example

Why Have Management Oriented Process Disciplines Disappeared?

If my observations are correct that these very valuable process disciplines have disappeared or are disappearing the question is why is this a problem, which I think it is? How can firms never engage or abandon such straightforward and powerful levers for organizational performance? If you will agree with my position that these disciplines are at least disappearing I propose the following reasons:

- While the logic of process discipline is fairly simple and straightforward, the value is in the details and this is actually very hard work. This alone could have firms try it and abandon the work or never try in the first place.

- We all know things change fast in today’s world. Many times no sooner have you mapped your process, gotten approval if needed, and implemented the change wisely that some issue is causing pressure for change in the process. For example, a function now wants inclusion in the process; someone has a new approach to automate the process or parts of it. Yet someone else wants even more streamlining and wants to take a functional area or two out of the process. The skeptic asks: why go through all of the hard work only to see the process change precipitously?

- Some have asked if processes really cause speed and re-work improvements. Or does something else like Agile or plain hustle or automation or some other thing really account for the speed and re-work improvements?

My response to #1 is yes this is hard work. But what that has lasting value does not require hard work? My response to #2 is yes things are changing quickly in today’s business world and I think this rate of change will not let up in the next two decades. But again, what is a firm to do other than hope this rate of change will go away? As for #3, my experience shows good process work is the biggest and most direct cause of speed increases and re-work decreases. Automation is interesting. A common knowledge aspect now in the process field is you do not want to automate a bad process. Design or fix the process first with good management-oriented process disciplines first then automate it if desired.

Where has good management-oriented process work gone? Subsumed in Agile or ERP systems? Replaced with newer management approaches? What do you think and if they are gone or disappearing is this a problem from your view?

This article is part of a series on what causes a firm’s value to increase.

Dr. William Bigler is the founder and CEO of Bill Bigler Associates. He is a former Associate Professor of Strategy and the former MBA Program Director at Louisiana State University at Shreveport. He was the President of the Board of the Association for Strategic Planning in 2012 and served on the Board of Advisors for Nitro Security Inc. from 2003-2005. He is the author of the 2004 book “The New Science of Strategy Execution: How Established Firms Become Fast, Sleek Wealth Creators”. He has worked in the strategy departments of PricewaterhouseCoopers, the Hay Group, Ernst & Young and the Thomas Group among several others. He can be reached at bill@billbigler.com or www.billbigler.com.